The USA has been central to the development of skyscrapers since technological innovations made taller buildings possible with Chicago’s 42 metre tall Home Insurance Building being recognised as the first skyscraper, opened in 1884.

The introduction of fireproof iron-framed structures with deep foundations, along with new inventions such as the elevator and electric lighting made it both technically and commercially possible to take buildings to new heights.

The skyscraper has continued to develop, becoming synonymous with the image of the United States, with ever taller buildings and grander architecture which provide office, retail and residential space in high-density cities. This revolution in engineering and building design obviously presented challenges for the maintenance of structures that were taller than anything seen before. As the industry leader, with over 50 years’ experience in facade access solutions, CoxGomyl is at the heart of the history and the future of the continuing innovations in North America and has been involved in some of the most exciting projects in the United States.

Formerly known as John Hancock Tower, 200 Clarendon was constructed in 1976 and is still the tallest building in all of New England. Over the years there have been a number of engineering challenges such as warping walls and the replacement of thousands of reflective glass panels. CoxGomyl were the company entrusted with overhauling the original 1970s window-washing systems and providing modern solutions for cleaning and care of the glass panels as well as practical access to the whole exterior. CoxGomyl partnered with ECM to assist with state-of-the-art laser scanning of the tower and its surroundings. ECM and CoxGomyl were able to provide a comprehensive analysis in order to perform a complete retrofit, matching the replacement parts of the new system with the existing parts of the old one.

In the city that was home to the very first skyscraper, 151 North Franklin is one of the most technologically advanced buildings in Chicago. It features unusually high ceilings of 10m on each of the 35 storeys, all with floor to ceiling glass panels to maximize daylight and offer stunning views of the Chicago skyline. This particularly demanding project specified a single building access solution that could access the entire facade including areas underneath signage, a platform rating of 453.59 kg and the capacity to accommodate three operators. The impressive BMU CoxGomyl provided met these requirements with 180 degree slewing capability in both directions and a maximum reach of 33.7m, extending with 5 jib stages. The large cradle is 9.14m long and the material hoist capacity is 680.38 kg, making up a facade access solution for complete coverage from ground to roof level.

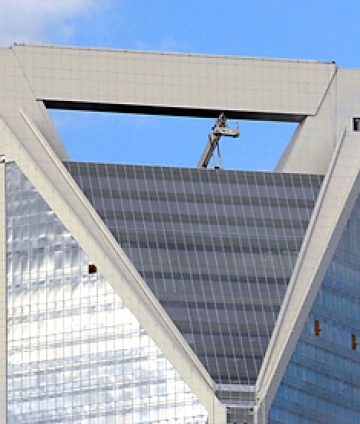

The Duke Energy Center, Charlotte

This distinctive building features a unique sloping ‘chisel’ design at the upper levels and a crossbeam over 20m above roof level, which presented significant challenges for facade access. The BMU needed a long reach whilst also being flexible and compact enough to manoeuvre into a very tight parking space. CoxGomyl designed and manufactured a five stage luffing jib for the specific requirements of this project which reaches all parts of the facade including the extreme corners. The cradle is fitted with a soft rope system to allow lateral movement and provide access to the sloping roofs and an innovative lift platform lowers the BMU into the parking pit when not in use.

From overhauling and modernising aging systems to designing bespoke solutions for the most challenging new skyscrapers, CoxGomyl is recognised for the expertise and experience they bring to every project in America and worldwide.