In the case of the 200 Clarendon, formerly known as the “John Hancock Tower,” CoxGomyl took on the challenge of installing a new window washing system for the 60-story skyscraper located in Boston, Massachusetts.

The Challenge

The newly re-named 200 Clarendon tower was designed by Henry N. Cobb of the firm I.M. Pei & Partners in 1976 and stands 60-stories tall in the heart of downtown Boston. It remains the tallest building in all of New England. This building has presented engineering challenges since its inception, from warping walls to the replacement of thousands of reflective glass panels upon completion of the original tower in 1976. CoxGomyl was recently hired to make sure the building had a system in place to meet the demands of the long-term cleaning and routine care of the glass panels and to provide solutions for easy access throughout the entire exterior of the building. With access to the rooftop being particularly limited, the reigning building expertise of CoxGomyl engineers paired with ECM’s 3D surveying experience and technology know-how, made for a valuable, turnkey solutions provider.

The Importance of Choosing the Proper Equipment

3D surveying experience alone will not guarantee the best results when it comes to the AEC industry applications. Experience and technique will only get you so far, and then the technology takes over. Understanding and adopting the science of measurement (otherwise known as metrology) to the world of construction, architecture, facility planning, and overall infrastructure becomes an extremely vital part of the entire process.

Using top industry brands like the FARO Focus3D X 330 Laser Scanner, ECM can provide full facility mapping surveys, as-built documentation, and 3D digital modeling layouts for a variety of applications. These model-based solutions help contractors like CoxGomyl to plan, design, construct, and manage their building projects. The 3D laser scanners used by ECM take digital images of their surroundings along with scanning points with extreme accuracy. The digital images are then matched to the corresponding scan yielding a true view of the project site.

The Solution

Always using the highest standard of quality solutions, CoxGomyl partnered with ECM to assist with scanning the top of the “Hancock

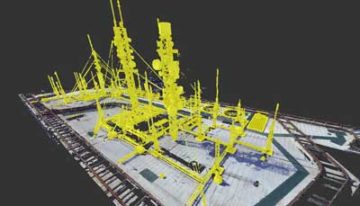

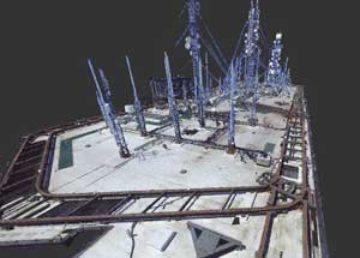

Tower” and its surroundings. This was accomplished by taking dimensions with the FARO Focus3D X 330 Laser Scanner to verify the existing conditions of the current window-washing system (built in 1976). Working together, ECM and CoxGomyl were able to provide a comprehensive analysis of the entire rooftop and the surrounding areas in order to perform a complete retrofit, matching the replacement parts of the new system with the existing parts of the old one. This report also included a point cloud organized into layers to help differentiate between the areas of the window washing system and to better organize the data set.

Return on Investment

Fairly new to the capabilities of laser scanning technology, CoxGomyl was looking for a team of experienced engineers to help them through the process. “After working with ECM, we now see the true benefits to laser scanning in our field of work,” stated Mile Damjanovski, Project Engineer for CoxGomyl. Damjanovski went on to explain that it can be extremely time consuming to send engineers onsite to take manual measurements when engineering large structures for buildings such as the 200 Clarendon Tower, sometimes taking several days to get all the data necessary to accomplish the job. With the help of ECM engineers, and laser scanning technology and knowledge base, they successfully captured the image of the entire rooftop in a matter of a few hours and had all the data they needed with just one scan. “This saved us so much time, money and resources,” said Damjanovski.

CoxGomyl found that by using laser scanning technology, coupled with the experienced engineers at ECM, they were able to capture and validate extremely valuable information they had previously measured by hand. By capturing this data and transforming it into 3D point clouds with the help of Autodesk® software, they were able to analyze the results from the as-built model that had shifted over the years providing them with the information they needed to build the system to the appropriate specifications. Additionally, they were able to capture various obstructions on the rooftop of the building to determine how they would work around them. “A key piece of information CoxGomyl wanted us to capture was the number of electrical outlets placed throughout the building, the size of those outlets and the locations, along with the specific dimensions telling their engineers how long they needed to make their cables for the window washing system,” stated Eric Rosenberg, Project Engineer for ECM.

The newfound ability to use laser scanning technology in their everyday work has been extremely beneficial for CoxGomyl. So much so, that is has now been implemented at a number of their locations around the world including countries like Spain, Australia, and the UAE. “The greatest benefit to hiring a company like ECM to help with this type of job is that it not only saved us time and money, but ECM did all the laser scanning work and reporting for us so that all we had to do was analyze the data and validate the results,” stated Damjanovski. With the success of this project, ECM looks forward to assisting more teams like CoxGomyl in their 3D laser scanning and Building Information Modeling needs.

ECM – Global Measurement Solutions is a leading metrology solutions contractor specializing in 3D Surveying and Building Information Modeling (BIM) services. Using the latest in laser scanning technology, ECM can create a digital record of the customer’s facility before or after the install.

Back to News